What are neon signs made of?

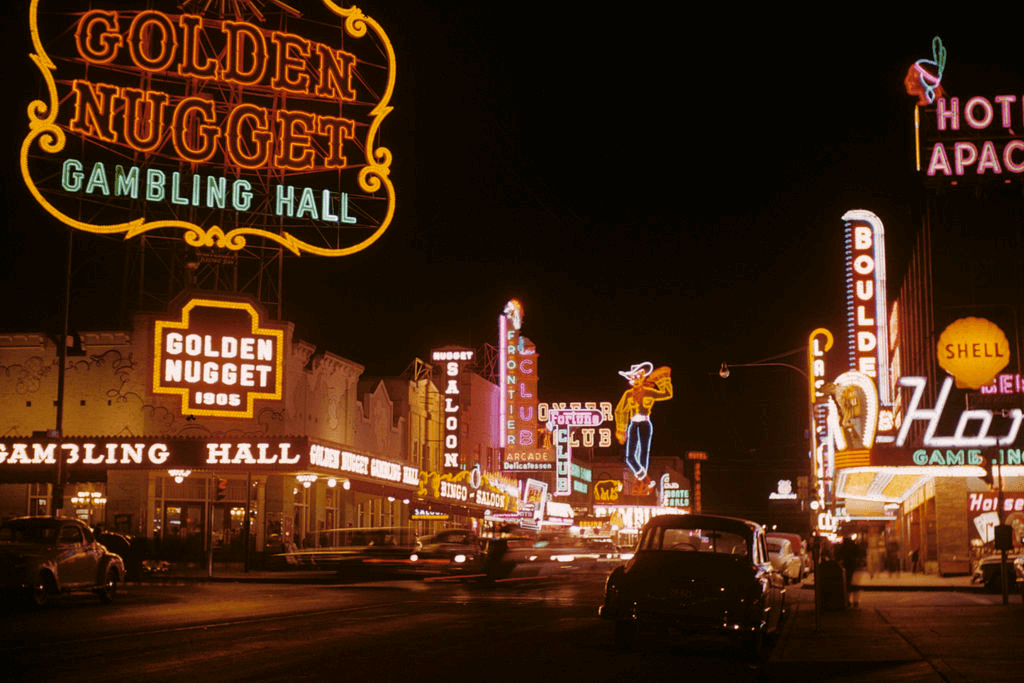

Neon signs are a classic form of advertising that illuminates the night sky with vibrant colors and sophisticated designs. Utilized for decades to draw attention to businesses and promote products, their unique appearance has become an icon. So, exactly what are neon signs made of?

The answer lies in combining various materials, all blending to create the distinctive glow of neon signs. From glass tubes to electrical wires, each component plays a crucial role in how a neon sign operates. Let's delve into the specifics of these materials and how they seamlessly combine to craft neon signs' luminous elegance.

The evolution of neon signs

What are neon signs made of? Neon signs have stood the test of time as a widely embraced method of illumination and advertising, gracing the windows of numerous businesses and the backyards of homes for decades. Crafted from a diverse array of materials, neon signs boast a captivating blend of glass tubing, metal frames, and essential electrical components.

At the core of neon signs lies the pivotal material – glass tubing. This tubing, filled with a combination of gases, undergoes high-temperature heating, causing the enclosed gas to emit a brilliant array of colors. Beyond the classic neon gas, signs may incorporate other gases like argon, helium, or xenon, each contributing to distinct hues and effects. The shaping of the glass tubing into desired forms requires the expertise of a skilled technician.

Metal frames play a crucial role in supporting the glass tubing and shaping the overall design of the neon sign. Typically fashioned from aluminum or steel, these frames can be adorned with a spectrum of colors. Their purpose is to securely hold the glass tubing in place, forming a sturdy foundation for the sign.

Complementing the glass tubing and metal frames are essential electrical components, including transformers, switches, and relays. Transformers serve to regulate the voltage from the power source, ensuring the proper functionality of the neon sign. Switches and relays, on the other hand, dictate the on and off timings of the sign.

Completing the ensemble, neon signs may incorporate additional materials such as rubber gaskets, mounting brackets, and seals. These elements contribute to the proper sealing and mounting of the sign, safeguarding it against weather and environmental conditions.

In summary, neon signs are an amalgamation of glass tubing, metal frames, electrical components, rubber gaskets, mounting brackets, and seals. This collaborative assembly results in a resilient and enduring sign, capable of serving as a powerful advertising tool across various applications.

>>>See more: how do led neon signs work?Standard components of a neon sign

- Power Supply Unit

- Neon Tubing

- Temporary Wall or Ceiling Hanging Chain

- Frame with Window Bumpers

- Connection between Electrodes

- Connection between Electrode and Transformer

- Support for Neon Tube

- "Bend Backs" for Neon Tubing

- Grounded Wall Plug with Three Prongs

- On/Off Switch

What are neon signs made of?

Traditional neon signs

What are exclusive neon sign made of? The primary components of a traditional neon sign include:

Tubes

Crafted from pliable lead glass (crystal), these tubes are meticulously shaped by hand through a process of heating, bending, and twisting. Subsequently, they are cooled and fused before being filled with diverse gases to produce a spectrum of colors.

Electrodes

Pure-iron electrodes, encased in a glass jacket, are affixed to both ends of the tube and connected to the transformer through high-voltage cables.

Transformer

This electrical device facilitates the transfer of voltage from the mains to the electrodes, essential for illuminating the neon gas within the fluorescent tubes. The process operates through electromagnetic induction.

Backin panel/framework

After the glass tubes are fashioned into the final design, they are either mounted onto a backing panel or supported by a framework. Smaller signs typically feature a steel framework, while larger displays may rely on wood, steel, or aluminum for support.

LED Neon signs

What are neon signs made of? LED neon signs, such as Xneonled, diverge from traditional neon signs by eschewing both glass and neon gas. Instead, they are crafted from acrylic—a thermoplastic widely recognized as Altuglas or Perspex—renowned for its lightweight, shatter-resistant properties and excellent light transmission capabilities.

The key components of a typical LED neon sign include:

Tubes

Derived from a solid block of opal acrylic, these tubes are meticulously shaped by rounding and sanding, providing a hollow space to accommodate the embedded LEDs.

Edges

The acrylic tubes are finalized with either blockout paint or vinyl edging, culminating in the creation of the ultimate design.

LEDs

Functioning as semiconductors, the LEDs (light-emitting diodes) are typically composed of aluminium-gallium-arsenide. These LEDs are strategically placed near within the acrylic tube and connected through wiring.

Backing panel

In cases where the design necessitates it, the tubes are affixed to a backing panel, which can be crafted from various materials such as polycarbonate, acrylic, or steel.

How neon signs are made?

What are neon signs made of? Neon signs are meticulously crafted from glass tubes, shaped into letters or intricate designs, and filled with inert gas. When an electric current is applied to the electrodes within the tubes, electrons travel through the gas, causing the atoms to emit light. The color of the light is determined by the type of gas present in the tubes.

In the case of a clear glass tube, argon gas produces a steel-blue light, while neon gas results in a red glow. To achieve a wide range of colors, over 80 variations can be created by coating the glass tubes with fluorescent powders. For example, placing blue-glowing argon gas in a yellow-coated tube generates a green light.

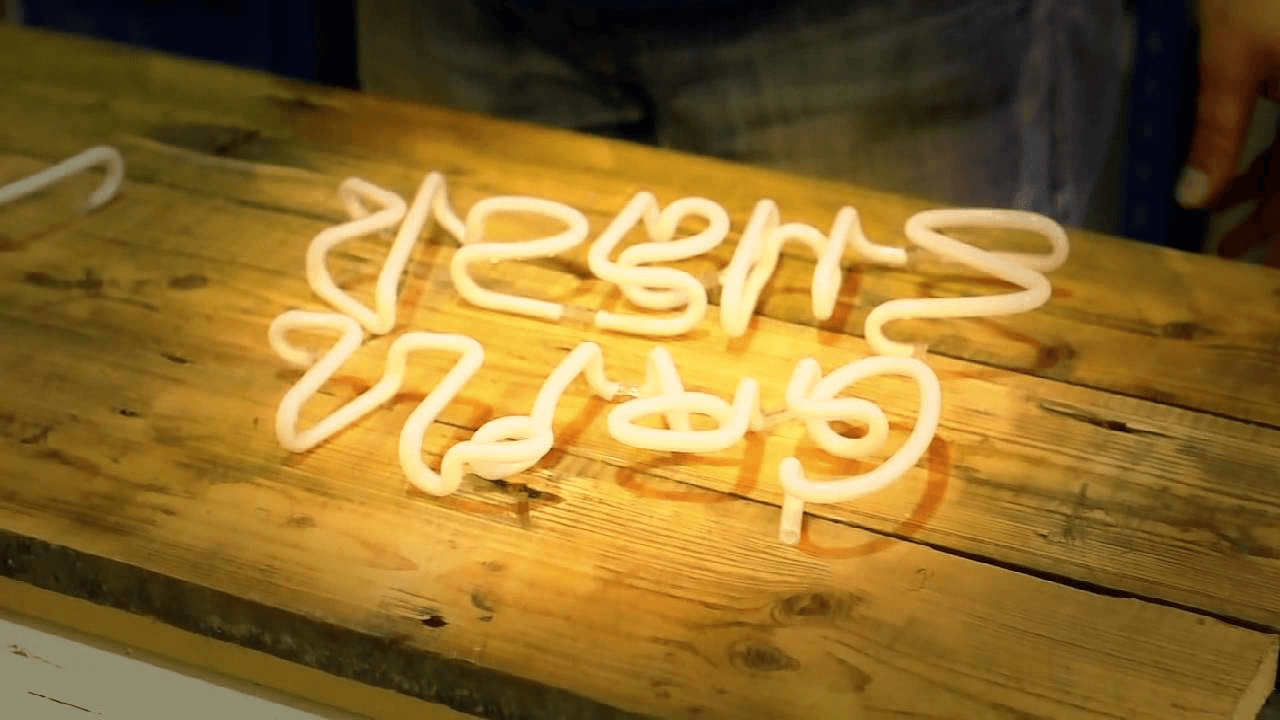

The tube-shaping process involves a glass blowing technique. Following a pattern on a fire-resistant sheet, the tubes are marked for bending. Each designated spot is heated using a ribbon burner with a propane flame at 1200°F, making the glass pliable within 30 seconds. After gentle bending, air is blown into the uncorked end to restore the original diameter, with each bend verified against the pattern.

Excess material is then trimmed, and any remaining powder residue is removed from the tube ends. Glass tube neon electrodes are attached by fusing them together using a propane hand torch and a flexible latex blowing tube. One electrode is sealed, while the other remains open. A tubulation, created with a crossfire burner, serves as a passage into the open electrode. A drop of mercury is added to enhance the brightness of the argon gas. Neon gas, used in red neon signs, does not require mercury.

Using an end torch, the open end of the tubulation is fused to a long glass tube connected to a pumping system. The electrodes are linked to the system, which vacuums out air from the neon sign and introduces the gas. The electrical current makes the gas atoms glow. To retain the gas, the tubulation is removed using the crossfire burner and the open electrode is sealed, ensuring the mercury has fallen into it.

Next, the back of the neon sign is dipped in black paint to enhance the visibility of the lettering and design. The sign is illuminated at high voltage for around 30 minutes, drying the paint and transforming the liquid mercury into vapor, which disperses throughout the sign.

Using transparent clips, the sign is mounted onto a black or clear plexiglass backing. Finally, the protruding electrode wires are connected to a neon transformer, converting standard 110-volt current into high-voltage current (3k to 15k volts) required to power the neon sign.

Conclusion

In this article, we have found out the answer “What are neon signs made of?” They come in a variety of colors and styles. Go to Xneonshop to choose the most affordable neon sign on the market.

For more detailed information and additional support, please contact us through:

- Website: https://xneonled.com

- Email: support@xneonled.com

Free Express Shipping

Free Express Shipping

49% Off

49% Off

12-Months Warranty

12-Months Warranty